In the globe of electronics and modern-day innovation, the relevance of printed circuit boards (PCBs) can not be overstated. A PCB, typically referred to as a circuit board, offers the important framework for connecting numerous electronic elements with conductive tracks etched onto non-conductive substratums. Among the many types of PCBs, the rigid-flex circuit boards stand out as a remarkable technology.

The production of PCBs, specifically in high-density interconnect (HDI) configurations, has progressed as the need for smaller, quicker, and extra efficient electronics boosts. HDI PCBs include finer lines and spaces, as well as smaller vias, which enable for better component density.

Collective endeavors with printed circuit manufacturers are critical in ensuring that PCB styles shift efficiently from theoretical stages to actual products. These manufacturers concentrate on various aspects, including PCB assembly and fabrication. They use products like FR-4, a flame-retardant epoxy material, which is extensively pertained to for its equilibrium of performance and cost-effectiveness. In the realm of high-performance applications, variations such as Rogers material, Megtron 6, and Megtron 7 are frequently used for their superior dielectric buildings and high-frequency efficiency. Subsequently, printed circuit card assembly (PCBA) ends up being a crucial action in the process where different components are soldered onto the PCB in precise arrangements to ensure optimal procedure.

Quick turn-around PCB prototyping services have actually obtained appeal as businesses strive to bring their products to market rapidly. With the enhancing accessibility of fast-turn PCB services, the barriers to prototype development have been substantially decreased, enabling an environment of innovation.

Flexible printed circuit boards (FPCBs) are another impressive classification that has gathered focus due to their distinct capabilities. These boards are created to be light-weight and ultra-thin, providing the ability to flex, fold, or spin without compromising performance.

Numerous manufacturers concentrate on developing flexible circuits, typically including sophisticated products and production techniques to improve efficiency and dependability. Thermal monitoring, for example, plays a vital role in PCB design, particularly in electronic items that operate under high lots. Engineers should think about products with excellent thermal conductivity, such as heavy copper PCBs, which assist dissipate warm successfully. Advancements like the back drill process are made use of to optimize signal integrity by removing excess material around vias, thus eliminating the potential for signal degradation.

The understanding of printed circuit board design is fundamental for designers and item designers. Knowing about numerous aspects such as circuit card assembly, that includes the process of soldering parts onto a PCB, check here can dramatically affect the end product's top quality. Reliable design techniques make certain that electrical paths are enhanced and that the overall format lessens disturbance, thus boosting life-spans and performance. Additionally, making use of tools and software created for PCB layout and simulation can significantly simplify the design process, enabling creators to quickly change prototypes based on screening outcomes.

Variations in PCB types such as 2-layer, 4-layer, and multi-layer boards are each matched to specific applications based on their intricacy and the number of elements that require to be integrated. Four-layer PCBs offer boosted transmitting capacities, vital for extra sophisticated electronics. These boards assist in handling signal honesty and provide enough space to route traces better, making certain more dependable performance in whatever from mobile phones to complicated commercial devices.

Contract PCB assembly services have actually come to be an essential source for companies doing not have the internal capacities to take care of intricate assembly procedures. These services commonly consist of detailed support ranging from design assessment to full-scale production, providing businesses with the adaptability they require to satisfy varying demands. By partnering with well-known manufacturers, organizations can utilize know-how in areas such as HDI layouts, microvias, and multilayer PCBs, therefore increasing their product offerings without investing greatly in devices and labor.

Choosing the appropriate products for PCB production is important, and considerations usually consist of the environmental criteria appropriate to their use, including UL ratings, such as 94V-0, which relates to terminate retardancy. Manufacturers need to remain informed regarding compliance regulations to make sure that their products satisfy safety criteria while also doing optimally in their designated application environments.

The combination of superhigh frequency (RF) technology right into PCBs is another area seeing raised significance, specifically with the rise of cordless interaction devices. RF PCBs should be meticulously designed, with considerations for insusceptibility control and minimized signal loss as a result of the high regularities involved. This expertise needs expertise of RF circuit design and might include in-depth electro-magnetic simulations as designers work to achieve optimal performance in small kinds.

As modern technology remains to evolve, manufacturers are increasingly adopting automation and advanced fabrication processes to enhance effectiveness. Technologies such as automated optical assessment (AOI) and surface area place modern technology (SMT) are currently typical techniques, permitting for high-speed assembly and regular quality assurance. Developments in PCB manufacturing likewise encompass new materials and techniques, such as making use of ingrained modern technology where elements are ingrained straight within the layers of the PCB, better conserving area and enhancing performance.

Whether with PCBA, flexible circuits, or fast-turn prototypes, the procedures, products, and designs associated with PCBs are vital in forming the future of electronic tools. With the ever-increasing intricacy of circuits and the demand for efficient, high-performance services, the PCB market stays a keystone of technological progress, driving the method we connect with tools and inevitably connecting our digital and physical worlds.

Katie Holmes Then & Now!

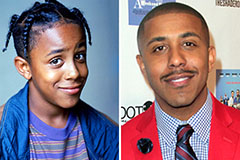

Katie Holmes Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!